|

|||||||||||||||||||||||||||||||||||||||||||||||

|

Úvodní stránka

Obsah

Titulní list

Editorial

Sklopné vrtule

Rorýs 29E

Návrh větroně (3. část)

Rychlostní polára

Slovník pojmů

Knihy

AL na DVD

|

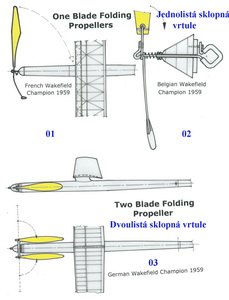

Folding propellers What are propellers and how do they work? A propeller is a part of a propulsion unit used in aicraft, airship, boats, fans, aeromodels, etc. The propeller propulsion unit for flying machines consists of an engine or motor, propeller and a gear box, if any. The propeller is mounted either on the engine or motor shaft or on the gear box shaft and rotates in the clockwise or counterclockwise direction. Each propeller has one, two, three or more blades. In aeromodeling propellers usually do not have more than four blades. A lot of full- scale flying machines use more- blade propellers. The distance between the propeller tips is called propeller diameter. This numerical value is the first important number marked on each professional product. The second important number marked on propellers is the propeller pitch. It is a designed distance which can the propeller reach during one revolution. The propeller executes two kinds of movement. The first is the turning(to the right or left) at chosen revolutions. The second one is the forward moving when a model flies. Each body moving trough the air creats a drag, without exception. And it is also the case of propellers. The propeller creats drag during the powered flight and also when the propulsion unit is off ( it is gliding). The aeroplane performance and flying properties ask to minimalize the drag. How to do it with propellers? Use the folding props, sounds the easy answer. We must say that the folding propeller is not any new design of the propulsion units. This solution was used many years ago and helped to increase the performance approximately for example of the Wakefield and Coupe d’Hiver models significantly in the 50s. Before the folding propellers aplications there were used idling propellers. It was a beter solution than the fixed prop, but not so much. Greater progress was brought by the folding propellers. What are folding propellers? The blades of these propellers are not fixed at their positions. They are folded backwards when the propulsion unit is off. The drag decreases dramatically and the performance of each flying machine increases significantly, when gliding. It is a solution for all cases when the total flight consists of a powered part and then of a gliding one. The folding propellers units are not for example the retracteable power systems where the fixed prop are retracted into the fuselages. The folding propellers were used in free flight classes of models powered by the energy from the twisted rubber threads many times before. In that time there were used one- blade and two- blade propellers. See Fig.s No 1, 2 and 3. There are examples of three Wakefield models from 1959. In Fig.s 1 and 2 there are one -blade propellers with balast on the oposite side for static balance at turning. In Fig. 3 there is shown an example of a two-blade folding propeller used on the German Wakefield.

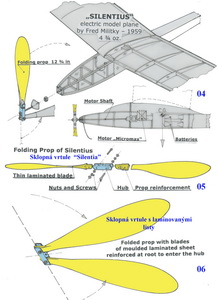

When the thrust of the spring, located on the motor shaft between the hub and spin, overcomes the tension of the rubber motor, the propeller finishes the turning and the blade or blades are folded back to the fuselage. Each blade has a small holder near the root to help blade to fold when the motor is not turning ( the powered flight was stopped). The rubber thread connecting the blade and hub then pulls the blades back. As close to the fuselage as possible. The bigger enlargement of folding propellers came with the development of electric motors and batteries. The first succesfull flights were reached by the German Fred Militky in 1959. See Fig.s No 4, 5 and 6. He used the designe, experiences and building methods of Wakefield models together with a light motor and batteries. The name of the model was “Silentius“. Two blade folding propeller was made of molded laminated sheet reinforced at root to enter the hub.

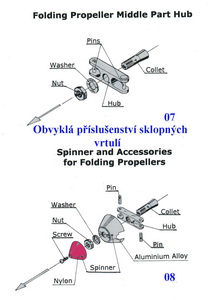

And how is it today? A folding propeller has usually following accessories : a hub, collet and spinner, see Fig.No 7 and 8. To them there belong pins, washers, nuts and screws. In Fig.No 9 there the hub which attached to the motor shaft by two grub screws is shown. There is not any collet. This solution could be a cause of a propulsion unit unbalance if the axis of a hub hole is not identical with the axis of the shaft.

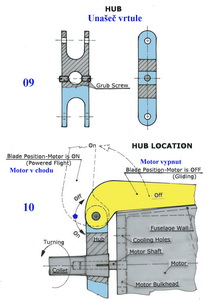

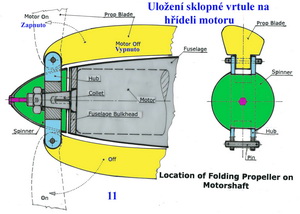

In Fig.No 10 the hub location on the motor shaft is shown. You can also see the location of blades when motor is on and when it is off. In Fig.No 11 an example of the folding propeller location, with all accessories, on the motorshaft is shown. That is nowadays most often used solution for electric propulsion units. You can buy all parts for folding propeller propulsion units in shops. Examples of them are in Fig.s No.12, 13 and 14.

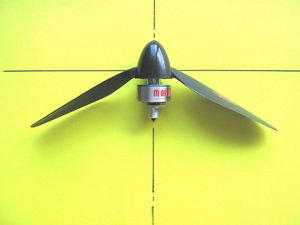

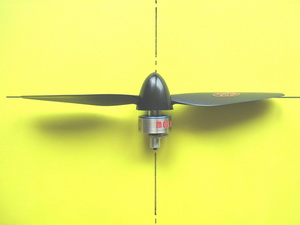

In Fig.s No 15,16 and 17 there are examples of folding propeller propulsion units with brushless motors. There are molded blades of plastic used.

In Fig. No 18 there is an example of a wooden folding prop. In Fig. No 19 there are shown my own prototypes of small wooden folding props. In Fig. No 20 there are some molded blades of folding propellers from professional workshops.

From Fig.s No 21(motor off), 22(low revolutions), 23(higher revolutions), 24(operating revolutions) and 25(maximum revolutions) you can see the blade positions when the motor is off and when it is fully loaded. See the changes of blade positions towards the motorshaft axis.

The blade of molded folding propeller is shown in Fig. No 26. The propeller of the diameter of 600mm is made of carbon-kevlar clothes and can change the pitch before taking-off. In Fig. No 27 and 28 there is a view of the hub of three- blade carbon-kevlar propeller with a posibility to change the pitch on the ground(before taking-off). Fig.s No 29 and 30 show the same three- blade folding propeller of a diameter of cca 650 mm.

Advantages of folding propellers: 1.significant drag reduction in gliding flights 2.there is no necessity of the prop dynamic balance if the hub is accurately manufactured. But the static prop balance is needed without exception. Disadvantages: 1.higher costs 2.a little higher weight 3.the very accurate manufacturing of the hub and collet. The conic hole in the hub must correspond with the conic surface of the collet. If not, the propeller is staticaly unbalanced in spite of the fact that the blades have the same weight and their C.G. are in same distance of the axis of rotation. It causes vibrations. Do not forget that the C.G. position of the model goes a little back when the propeller is folded. Folding prop propulsion units can be used for example in contests of Limited Motor Run. The task is a short motor run followed by a duration flight. Or anywhere you wish to combine the motor run with gliding.

Jaroslav Lněnička

28.-31. 5. 2009

|

||||||||||||||||||||||||||||||||||||||||||||||

| e-magazín Akademie letectví :: © Jan Janovec, © Jaroslav Lněnička :: akademie@airspace.cz | |||||||||||||||||||||||||||||||||||||||||||||||